Click on any image view it larger and read the captions easier

Our "cave" of a kitchen before remodeling

Like everything else in the remodeling of our house, the kitchen had to be done on a very tight budget with as little money as possible. We tackled the issue of a normally costly kitchen installation three ways.

The first way to cut costs was to purchase unassembled kitchen cabinets and do the assembly ourselves on site. The second way to cut costs was to install the kitchen cabinets ourselves. The third way to cut costs even further was for us to build the countertops ourselves and then tile them ourselves.

Naiveté is such a beautiful thing sometimes. We didn’t have any experience doing any of the aforementioned work. But we had our handy-dandy Home Improvement 1-2-3 book from Home Depot with straightforward directions and illustrations, so we thought, “How hard can it be?”

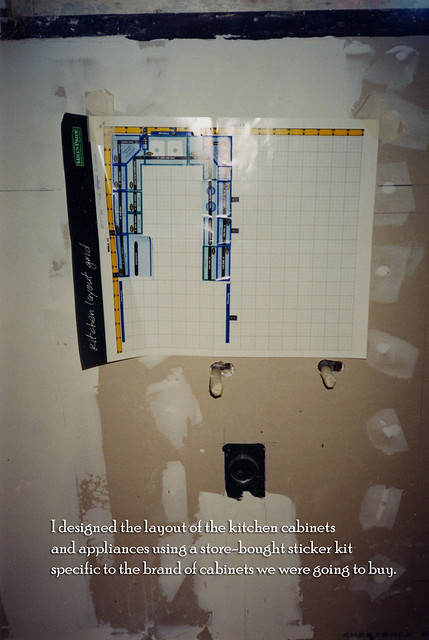

The first thing we bought was a ready-made layout kit made by the manufacturer of the cabinets we were going to purchase. It included a large page with a layout grid as well as sheets of various assorted stickers in perfect scale to the grid. The idea was to lay out the entire space using the provided stickers for walls, doors and windows. Then using the stickers for all the standard-sized cabinets for that manufacturer, you were supposed to lay out the kitchen (including standard-sized stickers for appliances). Once the layout was to your liking, you could go to Home Depot and buy the cabinets using the product numbers on each sticker in your layout.

So that’s what I did.

I’ve been drawing floor plans for fun since I was 8 or 9 years old when I had aspirations of becoming an architect when I grew up. Laying out the floor plan of our kitchen using the sticker kit was a real treat for me. I figured out exactly what cabinets could fit and what configuration was the best for the diminutive space.

After I was done, we went and bought the whole kit and caboodle of various cabinet kits and doors. We had to place an order because they didn’t have them in stock. Our order came in, we got all the boxes home and, before we started to assemble the cabinets, we took the time to watch the DIY instructional video that had come with them. It was dry and boring, but we didn’t want to do anything wrong so we watched it all the way through. Over and over the monotone narrator would instruct how to construct the box that would become cabinets using cams and bolts. Again and again he would warn, “Do not tighten at this time”. By the end of the video, the only thing we really remembered was “do no tighten at this time”.

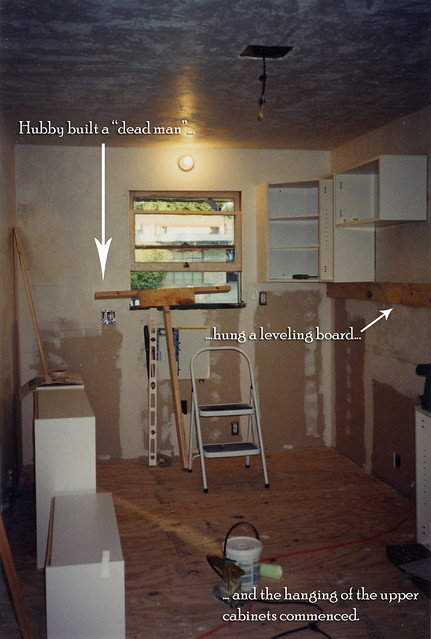

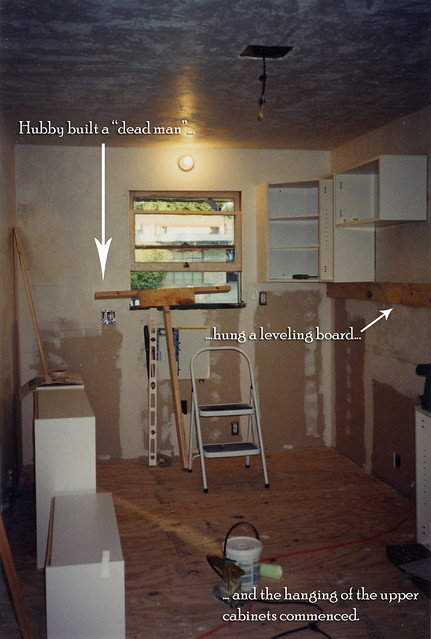

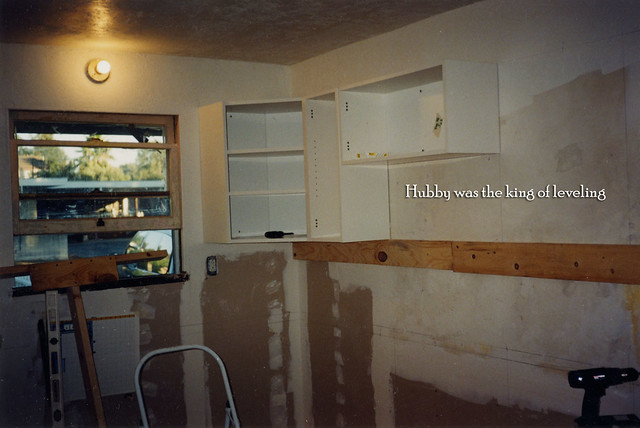

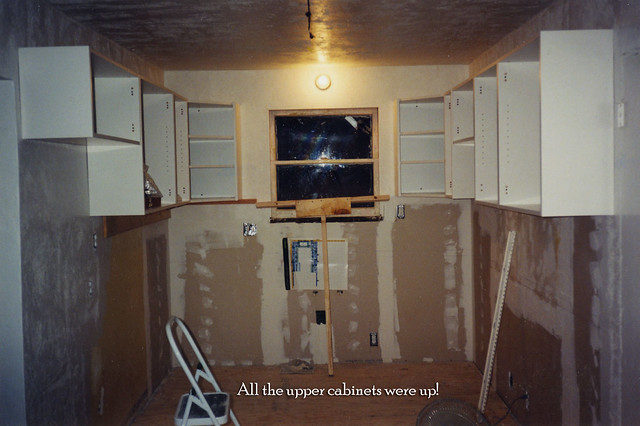

The upper cabinets had to go in first. Hubby built what is called a “dead man”—essentially a pair of 2x4’s in a T formation to prop under the bottom edge of a cabinet while attaching the cabinet to the wall. Hubby also installed a temporary leveling board on the first wall to aid in the process.

It was my job to put together the cabinets. I love puzzles and the assembly of cabinets (or furniture… even IKEA furniture) feels like putting together a puzzle to me, so I enjoyed it.

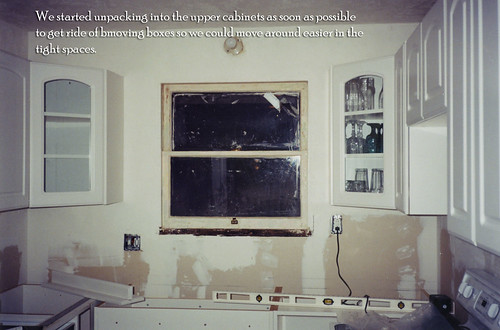

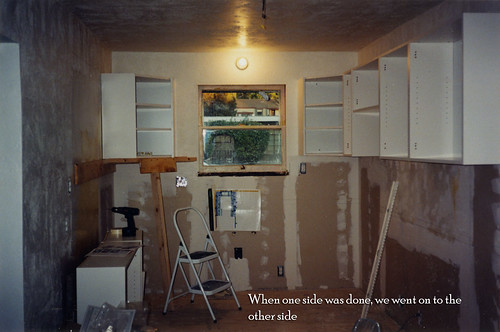

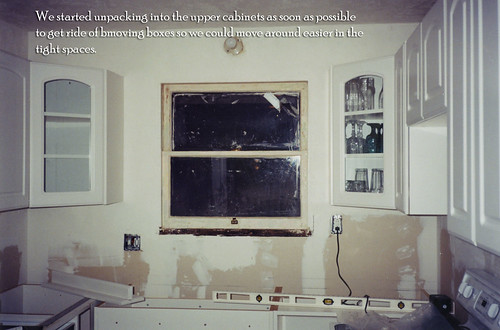

One by one each upper cabinet went up on the first wall until we were ready to begin hanging the cabinets on the opposite wall of what would be a galley-style kitchen layout. With each cabinet installation, we learned how to do it a little more efficiently and little faster.

After the upper cabinets were in, it was time to put in the base cabinets. Base cabinets are bit trickier in an old house with unlevel floors because you can’t simply draw a level line on the wall and hang them. Each cabinet has to be leveled independently with shims (triangular pieces of wood). Shimming made the process go slower than hanging the upper cabinets. But we managed to complete that too.

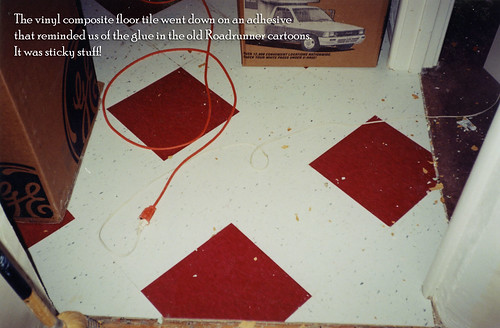

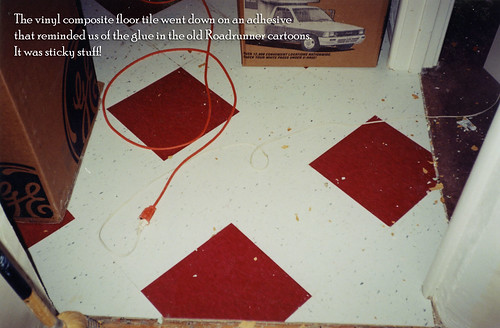

Once all the base cabinets were in, we could finally lay down a real floor on top of the plywood underlayment that had been our floor surface up to that point. We chose a vinyl composite tile (exactly like commercial floors) for its vintage look as well as its durability as we knew that during the rest of the phases of construction that the kitchen floor would have to survive a lot. The tiles (made by Armstrong) had to be installed using a caustic smelling runny adhesive that came in large buckets. The adhesive had to be troweled on with a specific toothed trowel, left to sit for a couple of minutes, and then the tile could be set on it. We learned to do workable patches of adhesive instead of trying to trowel large areas. We found ourselves laughing as we repeatedly got hands and shoes stuck on the adhesive because it was just like Wile E. Coyote in the old Warner Brothers Roadrunner cartoons with his “Acme glue” getting stuck on the railroad tracks right before a train bears down on him. We laughed as we joked about the possibility of a train barreling through our kitchen while we were stuck to the floor.

Once the floor tiles were all in place, we were able to move the appliances into their proper “homes” in the kitchen and free up much-needed floor space where they had resided after being delivered earlier than we were ready for them. I cannot express how wonderful it was to hook up the water line to the refrigerator and plug it in. The hum of an operating refrigerator was one of the best sounds in the world. We could finally keep food at the house because we could refrigerate it. And we had filtered and chilled water on tap! I never thought I would appreciate having a refrigerator so much. I was (and still am) reminded of how blessed I am to live where I can have this amazing luxury.

The next phase of the installation of the kitchen was the construction of the countertops. The original countertops had been tile, so we decided that we would stay true to the era of the house and put in tile.

Our archangel in overalls had gone back to university so we were on our own with this tiling job. Turning to our handy-dandy home improvement books again, we read up on how to build tile-ready countertops. Again, naiveté was a blessing. We dove right in and built the plywood underlayment on all the base cabinets and then, working as a team, we tiled the countertops the way we had seen my brother tile our shower. We borrowed Josh’s tile saw

he had used to tile our bathroom, and Hubby did the cutting while I did the measuring and laying of the tiles. I used the smallest tile spacers I could find so the grout lines would be the smallest I could make them. Then I went back in and grouted using a technique I came up with on my own. I put the grout in a large Ziploc bag and twisted it down like a cake decorating or pastry bag. I cut the tip off the Ziploc and piped the grout into the fine 1/16” grout lines before pressing the grout in with a grout paddle followed by a wipe down with a wet sponge. It worked! The grout has lasted for almost 11 years and is pretty easy to clean compared to wide grout lines.

You may have been a bit naive but you certainly had enough enthusiasm to make up for it.

ReplyDeleteWow, what a beautiful kitchen you have designed. I am shaking my head at the thought of all that work. You will laugh as we felt overwhelmed just replacing the floor, and the countertops...

Jen @ Muddy Boot Dreams

LOVE your kitchen! It's so fun and quirky. I'm trying to get mine to that place, but sadly it's devoid of natural light, which is tricky.

ReplyDeleteYay! A new installment. I'm so glad you're continuing with the story of Rosehaven Cottage. I've enjoyed reading about it so much!

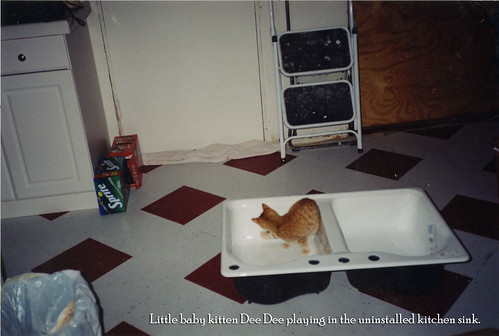

ReplyDeleteThis is adorable! Cats sure do love sinks, don't they?

ReplyDeleteI love the red accents. Very nice.

ReplyDelete